Reliable measurement results in any environment!

QNix® coating thickness gauges are versatile in use and meet the highest standards of precision and ease of operation.

Overview of measurement methods

Coating thickness measurement uses various physical principles to accurately determine the thickness of paints, coatings, or other layers. There are two fundamental methods: destructive and non-destructive testing.

Measure coating thickness quickly, efficiently, and without damaging the material.

| Feature | Description |

|---|---|

| Functionality | Measurement using magnetic or eddy current-based methods, without damaging the material |

| Application area | Ideal for paints, coatings, and finishes on metal or other substrates |

| Accuracy | Very high – delivers precise and reproducible results in second |

| Material preservation | No damage to the workpiece |

| Time required | Minimal – immediate results |

| Reusability of the test piece | Fully preserved |

| Example | QNix® gauges: robust, reliable, and intuitive to operate |

| Advantage | Fast, precise, and non-destructive measurement – ideal for quality control and mass inspection |

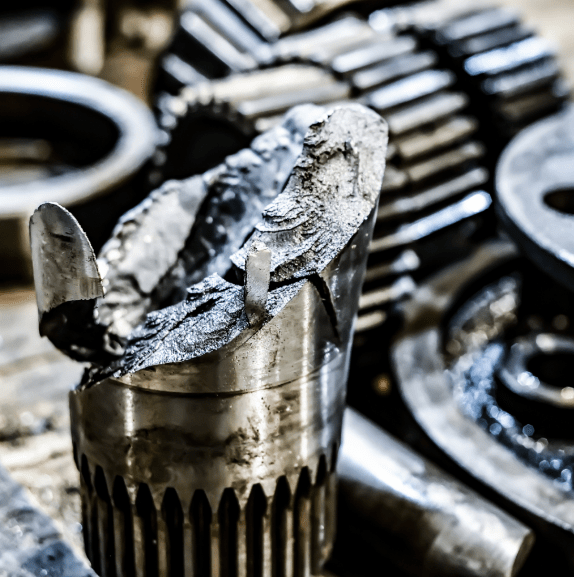

Destructive methods measure thick coatings but damage the workpiece in the process.

| Feature | Description |

|---|---|

| Functionality | The coating is removed mechanically or chemically to directly determine its thickness |

| Application area | Used when other methods reach their limits (e.g., very thick or complex coatings) |

| Accuracy | Precise, but dependent on manual execution |

| Material preservation | Workpiece is damaged or rendered unusable |

| Time required | Higher – requires sample preparation and post-processing |

| Reusability of the test piece | Not possible |

| Example | Cross-section or hole-drilling method |

| Disadvantage | Labor-intensive, expensive, and not suitable for mass inspections |

QNix® measurement methods in detail.

It uses two proven methods for fast, precise, and non-destructive coating thickness measurements that do not damage the object.

Where are QNix® coating thickness gauges

used?

QNix® gauges are used wherever metal surfaces are exposed to high stress and precise protection is crucial. Whether offshore facilities, bridges, pipelines, ships, production plants, or vehicles – accurate coating thickness measurements help detect deviations early, prevent damage, and ensure the quality, safety, and longevity of your components and equipment.

Offshore facilities

Wind and oil platforms are constantly exposed to saltwater, wind, and weather. QNix® gauges reliably check the protective coatings and prevent corrosion before damage occurs.

Bridge construction

Steel bridges are exposed to extreme weather and load conditions. With QNix® devices, every coating layer can be monitored, extending the lifespan of the structures.

Industrial plants

Tanks, pipelines, and production facilities are exposed to aggressive substances and high temperatures. Precise measurements ensure that every coating withstands all stresses.

Pipelines

Pipelines transport oil, gas, or chemicals through various climate zones. Precise coating thickness measurements detect material fatigue early and ensure the highest safety standards.

Shipbuilding

Ships withstand wind, waves, and saltwater. Submerged areas in particular require precise coatings. QNix® gauges ensure reliable protection and long service life.

Vehicle Assessment

Whether for appraisals, dealer evaluations, or bodywork repairs: QNix® devices detect repaints, document repairs, and ensure transparent and well-founded vehicle assessments.

Why QNix® is the best choice for your industry!

QNix® coating thickness gauges deliver absolutely precise results across a wide range of industries – even under demanding conditions. Whether for robust protective layers on metal or paint coatings in vehicle assessments, our devices operate reliably, providing fast, accurate, and straightforward measurements.

Those who expect the highest quality will find the right measuring device for every requirement with QNix®.